BARTEC is therefore setting new standards in the protective packaging sector with its innovative membrane packaging, which was implemented as part of "Project Green" in Bad Mergentheim, Germany.

The new special membrane packaging replaces the previously used foam packaging. It consists of an outer carton, two membrane pads with film, and perforated corrugated cardboard combs, which enclose the packaged goods tightly and hold them in place gently. Two additional inserts protect against possible damage. "This special outer packaging not only creates more space in the warehouse but also offers special protection against any impact and vibration for sensitive shipping goods weighing up to 35 kg thanks to floating transportation between two cushions. At the same time, BARTEC focuses on sustainability. This is because the environmentally friendly special membrane packaging is reusable and can be integrated into the paper and cardboard recycling cycle," says Markus Noe, Shipping Manager at BARTEC in Bad Mergentheim.

The reduction of CO2 due to the lower packaging volume positively impacts the environment and is an important step towards sustainability. In addition, the special membrane packaging enables greater flexibility in the packaging of new products, allowing BARTEC to react quickly to changing requirements.

Positive impact: Changeover Reduces Cost and Storage Volume

The introduction of the innovative special membrane packaging has resulted in numerous advantages and efficiency gains for BARTEC. The packaging changeover not only means a drastic reduction from 15 different packaging systems to just two systems in Bad Mergentheim, but also leads to a reduction in storage space from 53 to just six pallet spaces.

The cost savings associated with the special membrane packaging are the result of various factors, including the reduction in packaging materials required and the reduction in process costs in the areas of procurement, storage and shipping. The short procurement times and fast handling of special membrane packaging help to increase efficiency and ensure that our packaging process runs smoothly.

"Our mission goes beyond improving internal processes. We want to make a contribution to a sustainable future through intelligent packaging solutions," explains Markus Noe. "Overall, the switch to special membrane packaging means a holistic approach to improving our processes, cost efficiency, and environmental footprint."

Sustainable Packaging Alternatives

In addition to the new special membrane packaging, we are also focusing on sustainable and efficient packaging alternatives in other areas.

For example, BARTEC now uses cartons with automatic bottoms and self-adhesive closures that require neither adhesive tape nor dispensers. This not only simplifies the sealing and opening process, but also helps to reduce waste and costs.

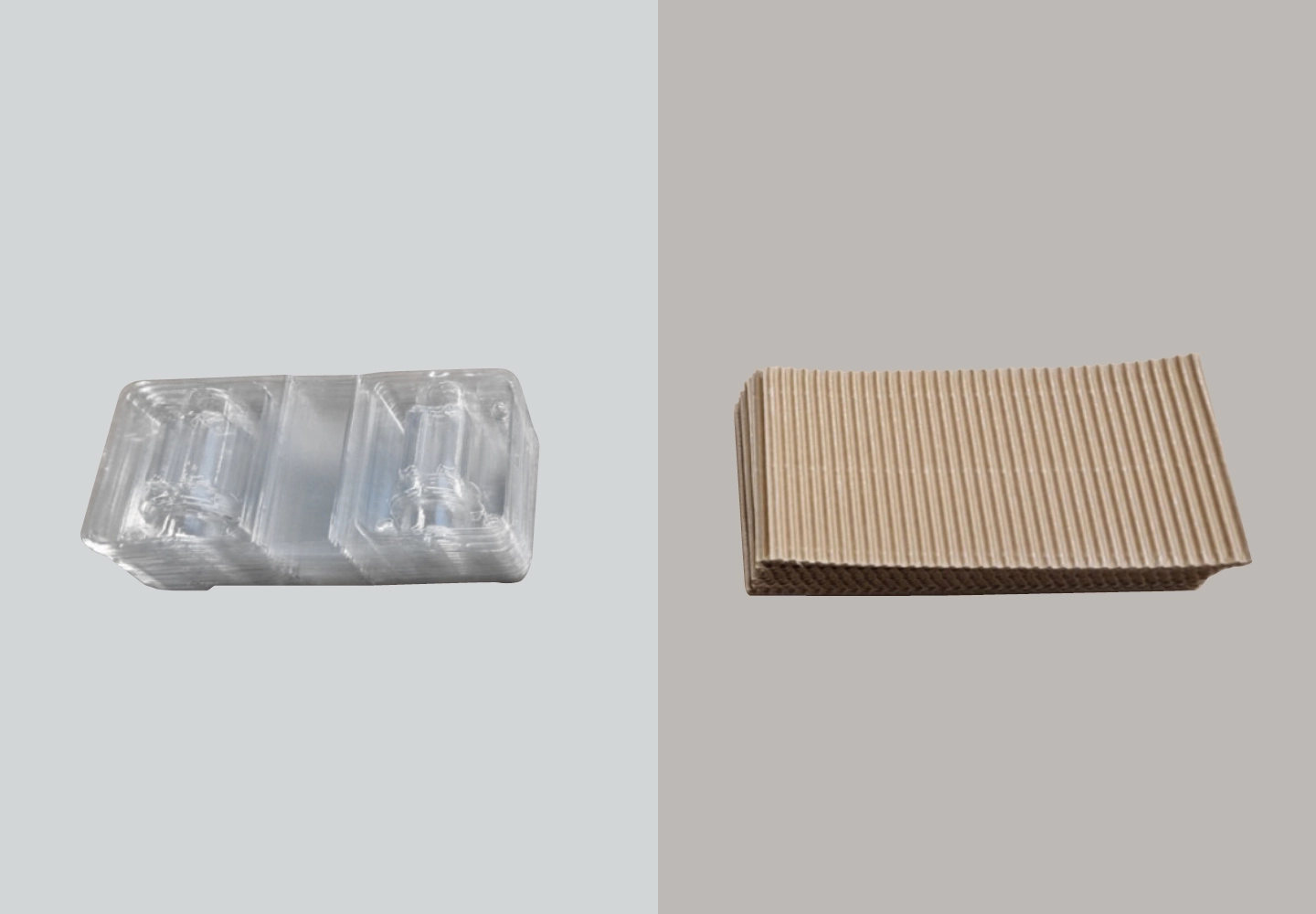

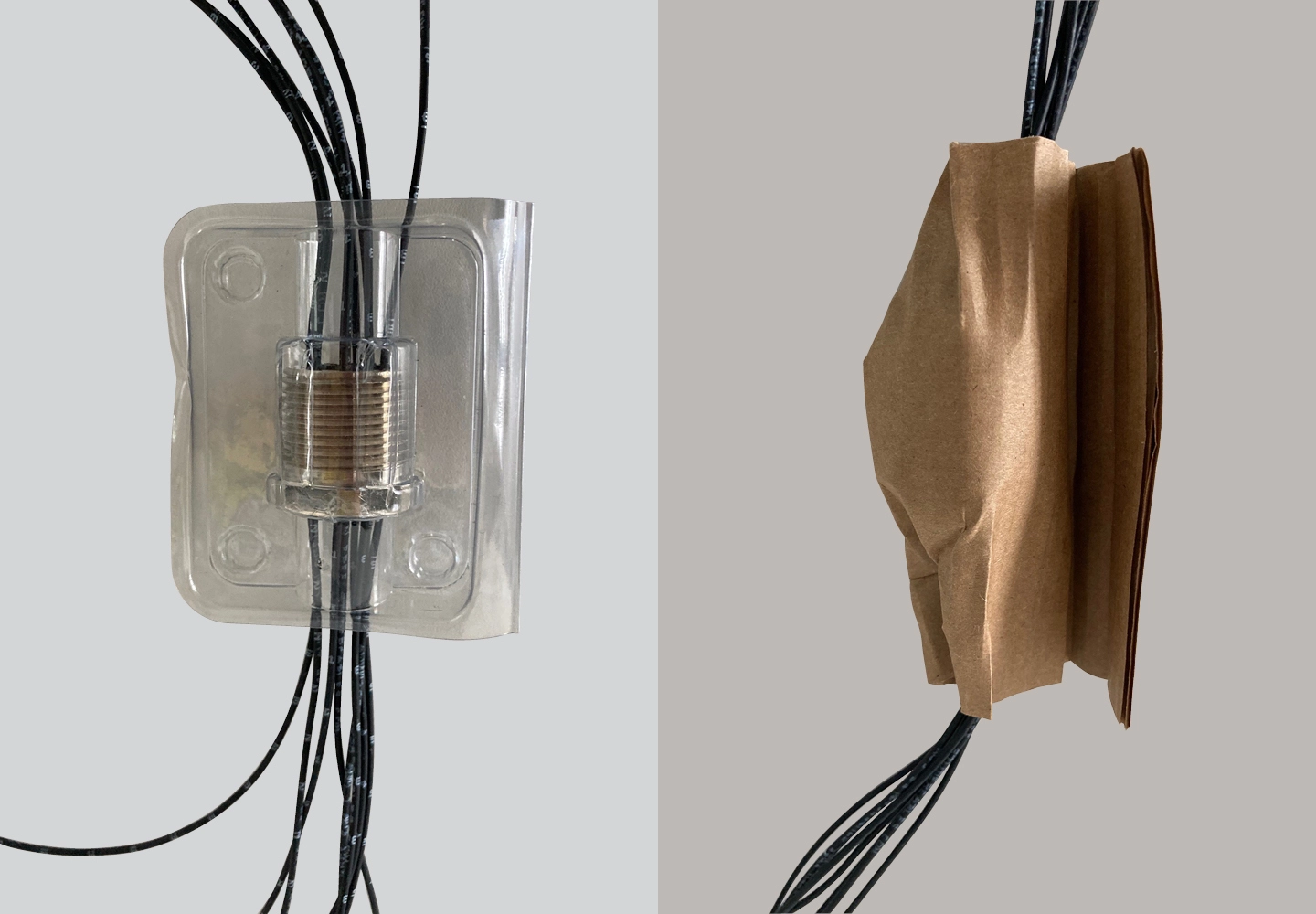

Another focus is on sustainable materials. The elimination of plastic adhesive tape not only helps to reduce plastic waste, but also enables the entire carton to be recycled easily. In addition, the filling material is now biodegradable. Delivery note bags made of plastic are being replaced by paper bags, and monowell packaging round off the "Project Green" concept which helps to reduce the ecological footprint and pave the way for more environmentally friendly processes at BARTEC.

New Sustainable Packaging for Line Bushing and Switches

Furthermore, we have also recently changed the packaging of our line bushing and switches from a plastic blister solution to a corrugated cardboard (mono flute) one, which is completely recyclable and environmentally friendly. This innovative solution aims to protect our products during the logistics phases so that they can reach their final destinations in the best possible conditions. On the other hand, this new packaging reduces its environmental impact by using 100% recyclable materials manufactured using minimal impact on energy consumption and natural resources.

We share our commitment with our customers, employees and shareholders as we fully believe that environmentally friendly solutions are key for the future of our business. This new packaging is a further step towards our sustainable vision which will have positive impacts on our customer supply chain.

''As a worldwide leader in explosion protection, customers expect from us innovation from all sides: productwise of course but also in terms of green and sustainable solutions, when possible,'' highlights Simon Dyhringer, BARTEC ESS Product Manager – EX components.

In line with the changes in global landscapes concerning the environment, BARTEC is also making changes to decrease its environmental footprint. With the introduction of sustainable membrane packaging and 100% recyclable packaging for line bushing and switches we are starting to shift from plastic materials to the ones that are 100% recyclable thus reducing the environmental impact of our products, but also increasing the efficiency of our operations.